How Sheroz Earthworks can Save You Time, Stress, and Money.

What Does Sheroz Earthworks Mean?

Table of ContentsGetting The Sheroz Earthworks To WorkIndicators on Sheroz Earthworks You Need To KnowSheroz Earthworks Can Be Fun For EveryoneHow Sheroz Earthworks can Save You Time, Stress, and Money.Sheroz Earthworks for Dummies

For any earthwork service provider, it is essential to carry out collaborate with top quality, accuracy, and on routine. Making use of maker control in job makers enables enhancing the different phases in the earthwork process, from preparing to the upkeep phase - fj dynamics autosteer review. The equipment control system helps the equipment operator in acquiring the target airplane quickly and easily

The maker control system guides the driver with centimeter precision. Remote support conserves time and cash, as it minimizes downtime in jobsites.

The Of Sheroz Earthworks

Our system's elements are thoroughly developed to withstand the rough conditions of construction websites. Comparison of the exact same task implemented utilizing device control versus the typical method reveals that, on average, the traditional strategy requires 50% even more time to accomplish the exact same job as the technology-assisted method.

Enter the Xsite machine control system; it's here to give you with a substantial advantage when working with earthmoving equipment. Discover how Xsite Equipment Control can enhance your efficiency and make sure work security! Xsite Equipment Control systems can be installed to any type of excavator from mini excavators to large mining excavators.

How does maker control work? In 2D systems, the equipment is furnished with calibrated inclination sensors. These sensing units are placed on the pre-determined components of the machine in excavators the sensor are normally installed to the framework, boom (or booms), miner arm and to the quick coupler - trimble gps. By utilizing the data obtained from these sensing units the system can determine the exact position of the excavators bucket idea in significance to a recommendation point.

The system is extremely easy to learn the fundamentals can be instructed in under one hour of training. Exactly how does the remote assistance job? A cordless web connection makes it feasible to establish a remote connection between the maker control system and the solution.

Excitement About Sheroz Earthworks

Xsite Maker Control systems support open standard data styles, enabling seamless info circulation from one system to an additional. Depending on your choice of system (with or without positioning, i.e., 2D or 3D), your equipment is outfitted with inclination sensors, a controller device, and a display/operating panel.

Lots of hardware and software program remedies exist to aid figure out an equipment's current position on the earth and contrast it with a preferred layout surfaceand building and construction drivers can do more to utilize the benefits. Maker control is making use of numerous positioning sensors and a display to offer the driver with a reference in between the placement of the bucket or blade and the target grade.

Relying on the setup, machine control systems can supply the driver with a straightforward aesthetic guide to bucket or blade setting, or can automatically move the blade to quality by speaking to the maker's hydraulics - https://papaly.com/categories/share?id=2fb5cd080ed44e92a364571e3aef5522. There are device control systems readily available for simply concerning any type of equipment: , dozers, excavators, soil and asphalt compactors, scrapes, trimmers, milling makers, and pavers

Getting The Sheroz Earthworks To Work

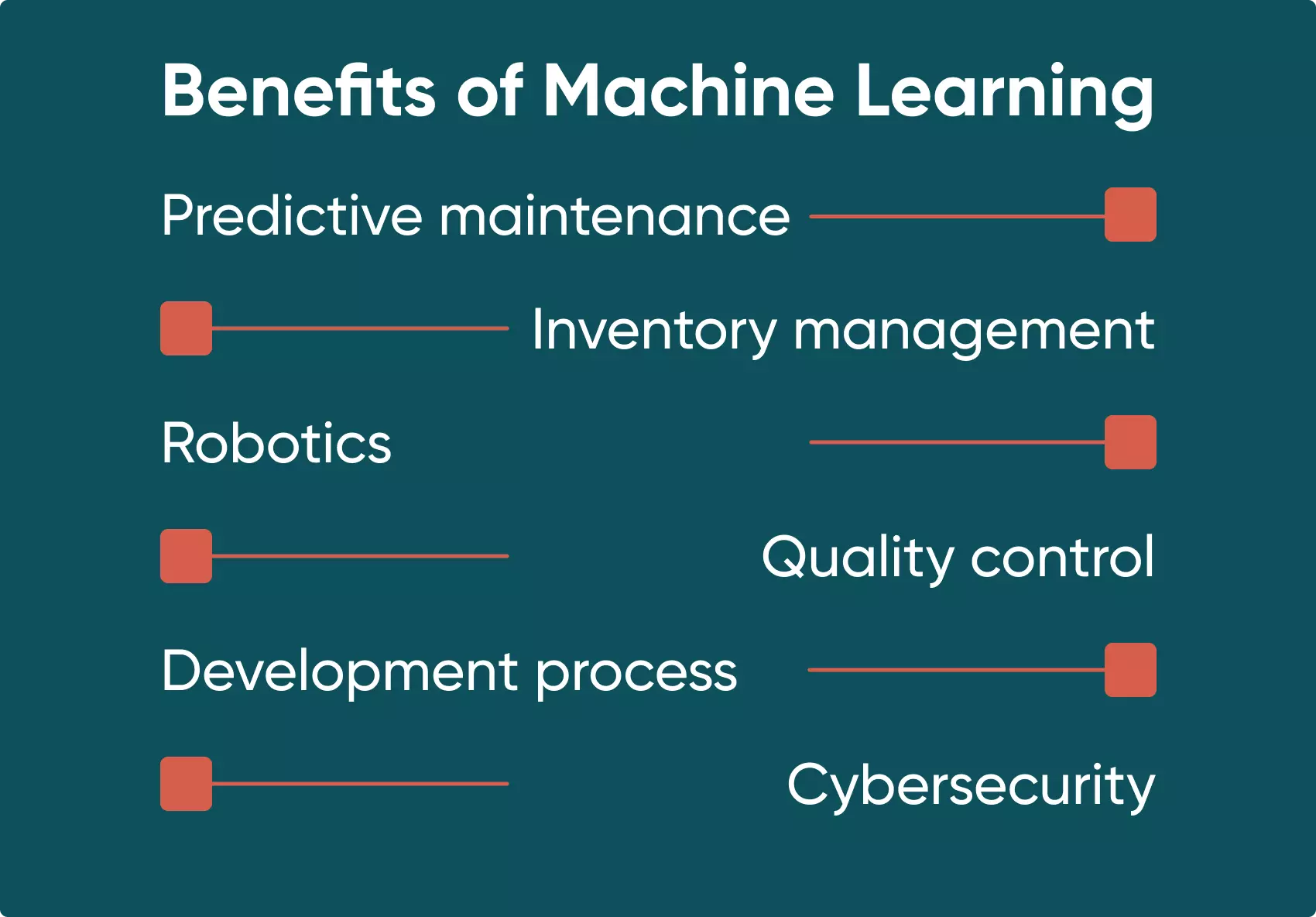

Some advantages include reduced rework, enhanced task effectiveness, and lower surveying prices. Equipment control can also help enhance efficiency and minimize total costs. This innovation is altering the means the construction industry works. Construction tools without equipment control will end up being a distant memory and the benefits obtained from it will certainly be various.

Trimble equipment control systems provide a myriad of advantages to any individual who uses earthwork equipment and, at EarthCalc, we can offer you with 3D declare your machine control-enable devices. Not sure if maker control is worth the expense? Take into consideration the complying with reasons you require to consider this choice.

Using GPS lined up with your 3D design documents, these systems essentially guarantee that you will eliminate or put the proper quantity of product at the construction website. On the majority of building sites, rework is an usual and irritating reality, however with Trimble equipment control, you can eliminate the requirement for rework.

Sheroz Earthworks Can Be Fun For Anyone

Typically, with Trimble device control, you can remove excess devices at a specific job website. A work that could have required the usage of 3 or browse around these guys 4 items of excavating tools currently might require only two items of equipment to accomplish the same job in much less time. This allows you to relocate your equipment to one more work website and take care of multiple jobs at once.